DESIGN ADVICE

When preparing a file for laser cutting;

FILE FORMAT SELECTION

Since CAM programs are mathematics-based, they might not correctly read images with pixels or scanned files. Instead, vector files that can contain information such as coordinates or dimensions should be preferred. Our programs can only process files in .dxf and .dwg formats, so files sent in different formats need to be converted to .dwg format, and sometimes data losses can occur during these conversions. Therefore, sending your cutting files directly in .dwg or .dxf format will prevent possible errors.

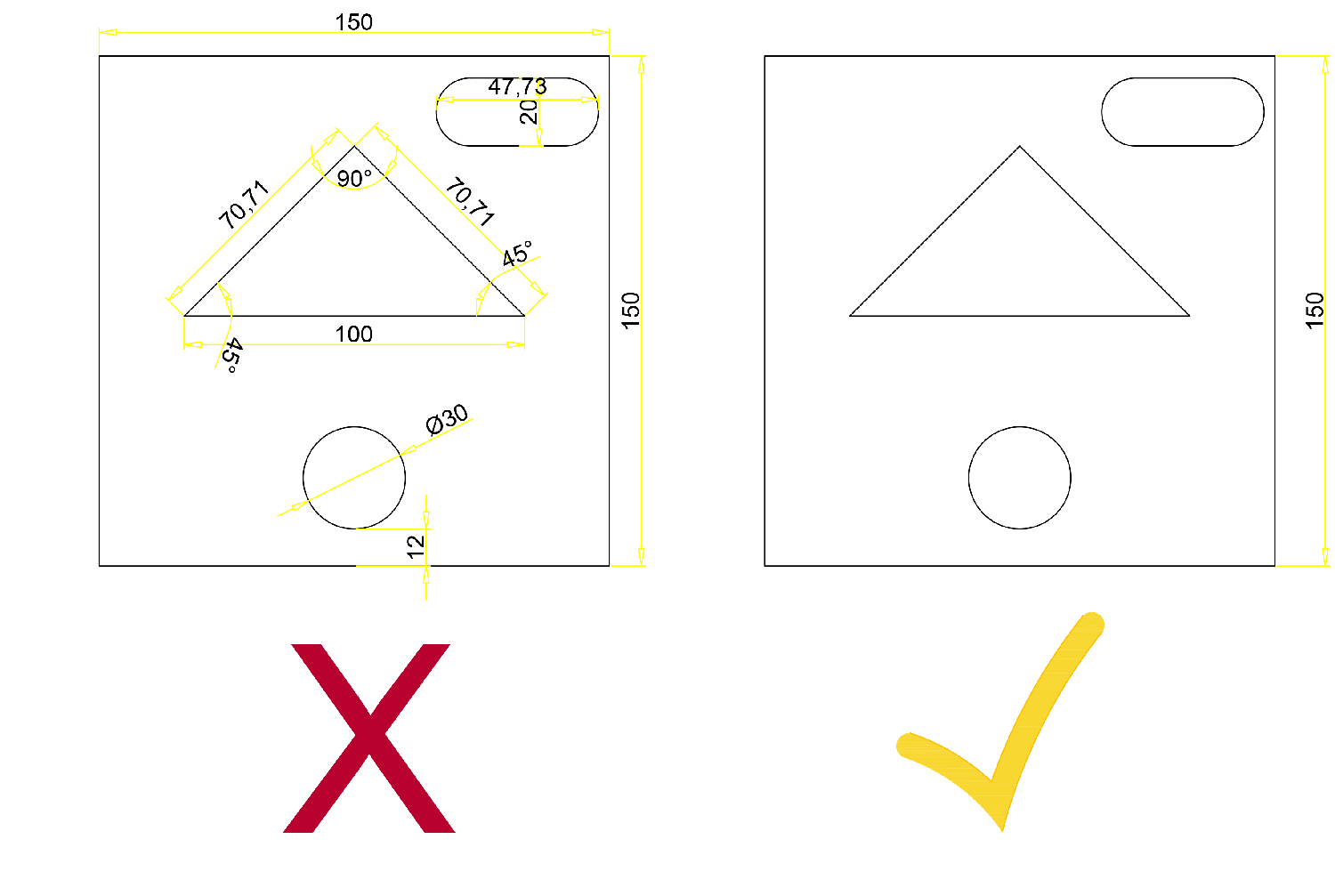

SCALE AND DETAIL

In the files you will send to request a quote; having the drawings of the parts scaled 1:1 and not including details other than the cutting paths of the parts in the drawings will help us deliver your quote faster.

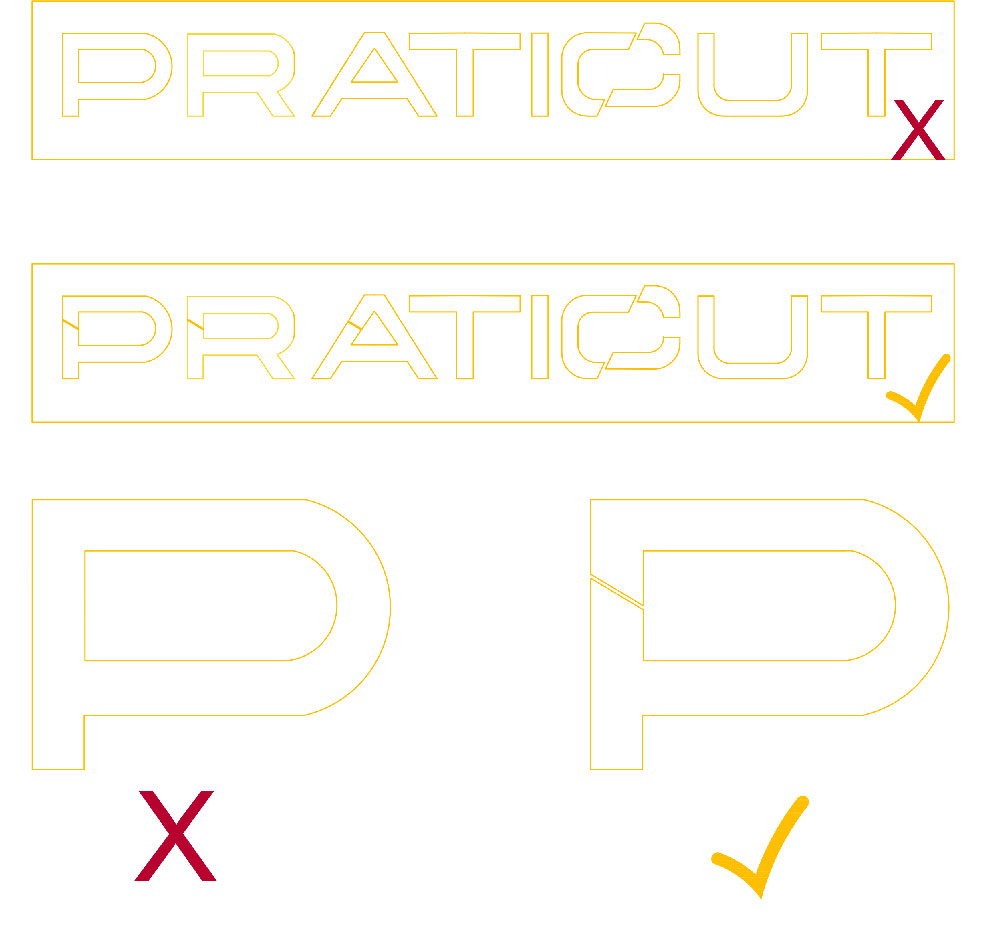

DESIGNS OF LETTERS AND NUMBERS TO BE LASER CUT

When designing letters and numbers containing closed loops such as A, B, D, O, Ö, P, Q, R, a, b, d, e, g, o, ö, p, q, 4, 6, 8, 9, 0, connecting bridges should be used.

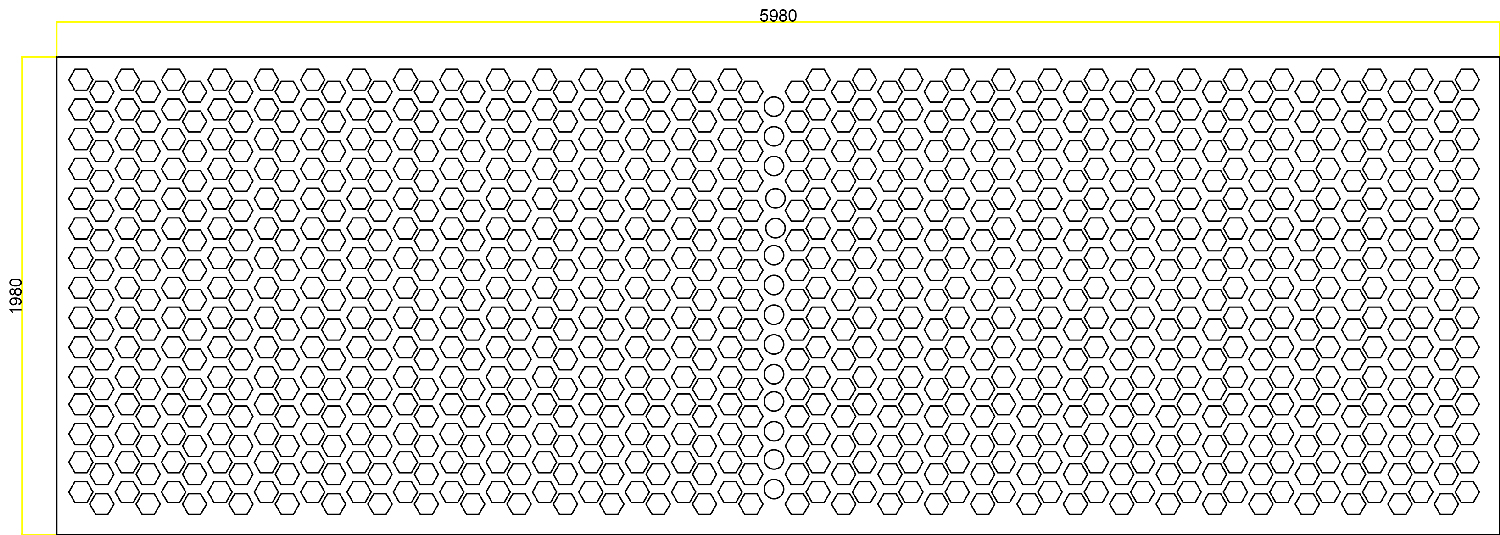

MAXIMUM USAGE DIMENSIONS OF PLATES

A 10 mm cutting margin is left on the edges of the plates to be cut with a laser. If you are designing to fit into sheets of 1500mm x 6000mm dimensions, remember that the plates can be used in maximum dimensions of 1480mm x 5980mm.

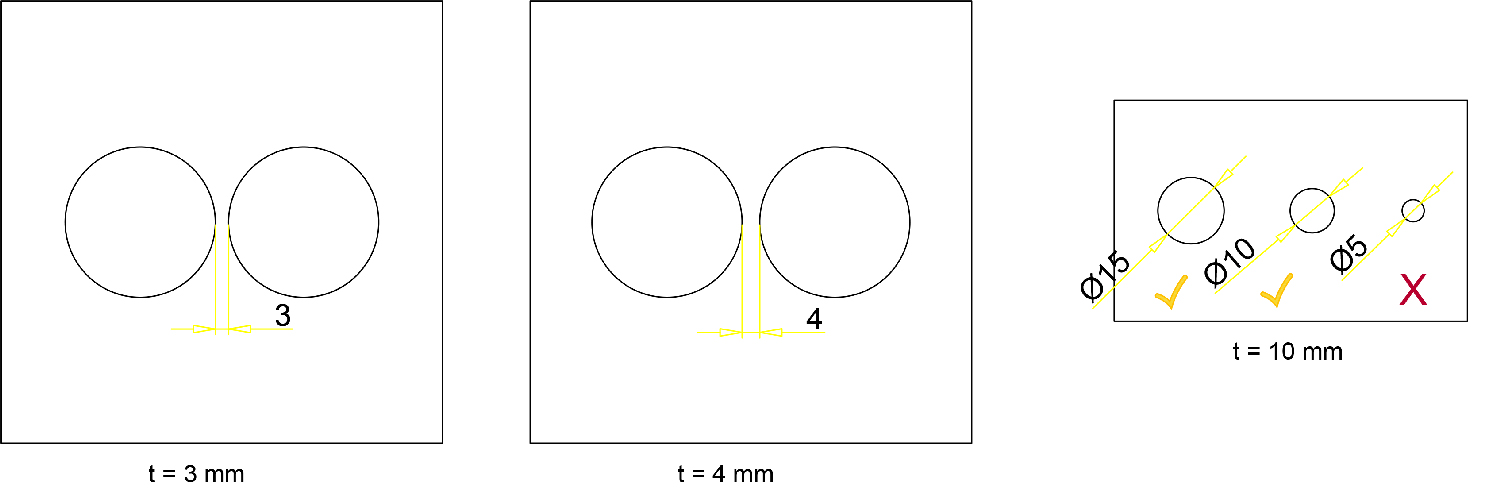

DISTANCE BETWEEN TWO CUTS

There should be a distance equal to at least the thickness of the sheet between cuts. For example, when cutting a sheet of 3 mm thickness, a minimum distance of 3 mm should be left between two cutting points.

HOLE DIAMETERS

The hole diameters of the parts to be laser cut should be at least as thick as the sheet thickness. For example, for holes in a sheet of 3 mm thickness to be cut, the hole diameters must be 3 mm or wider.

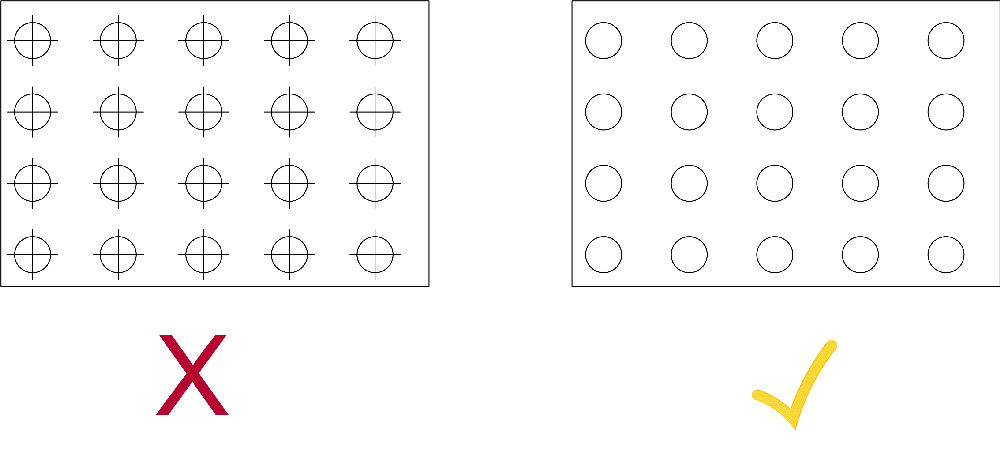

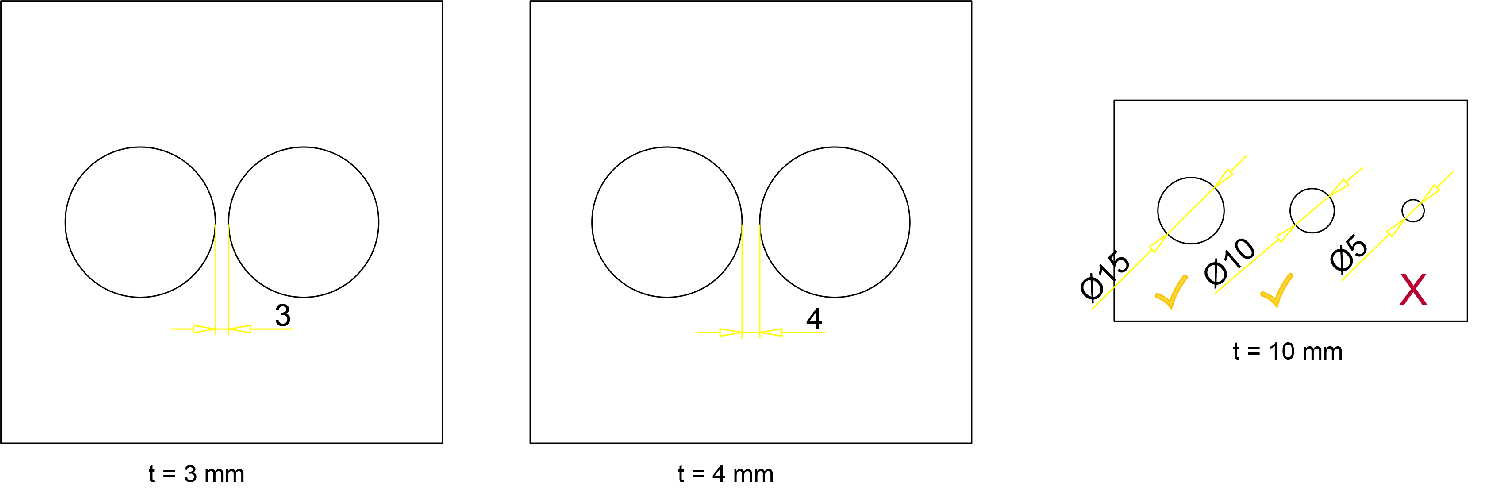

COMMON ERRORS

CAM programs perceive repeating, overlapping, or free lines and points as additional cutting paths, even if they are not visible. This can lead to incorrect calculation of cutting time and, consequently, incorrect pricing.

Avoid elements in your designs such as non-intersecting lines, curves, and similar cutting paths that could prevent detection.

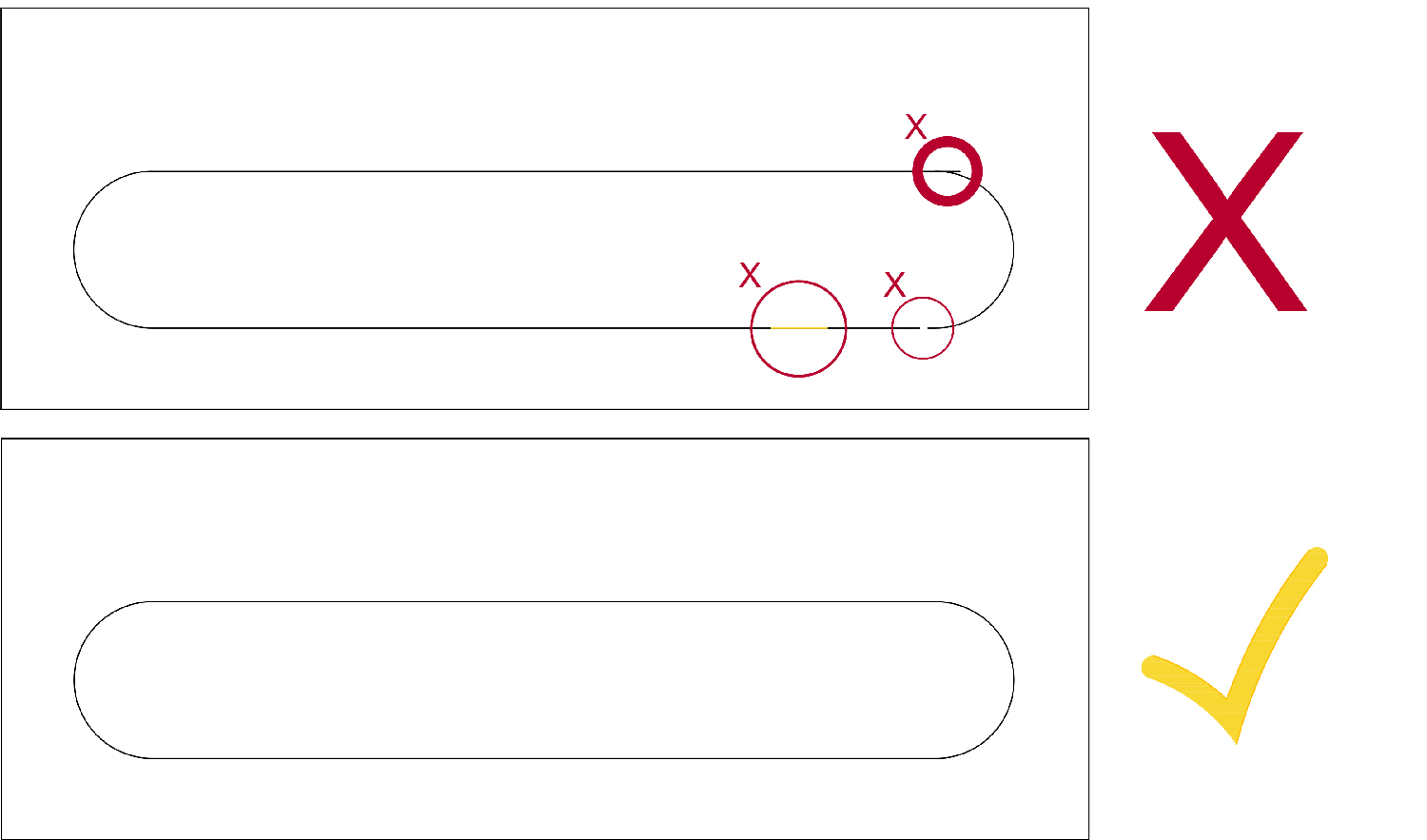

PRESS BRAKE BENDING

It is one of the most commonly used cold forming methods.

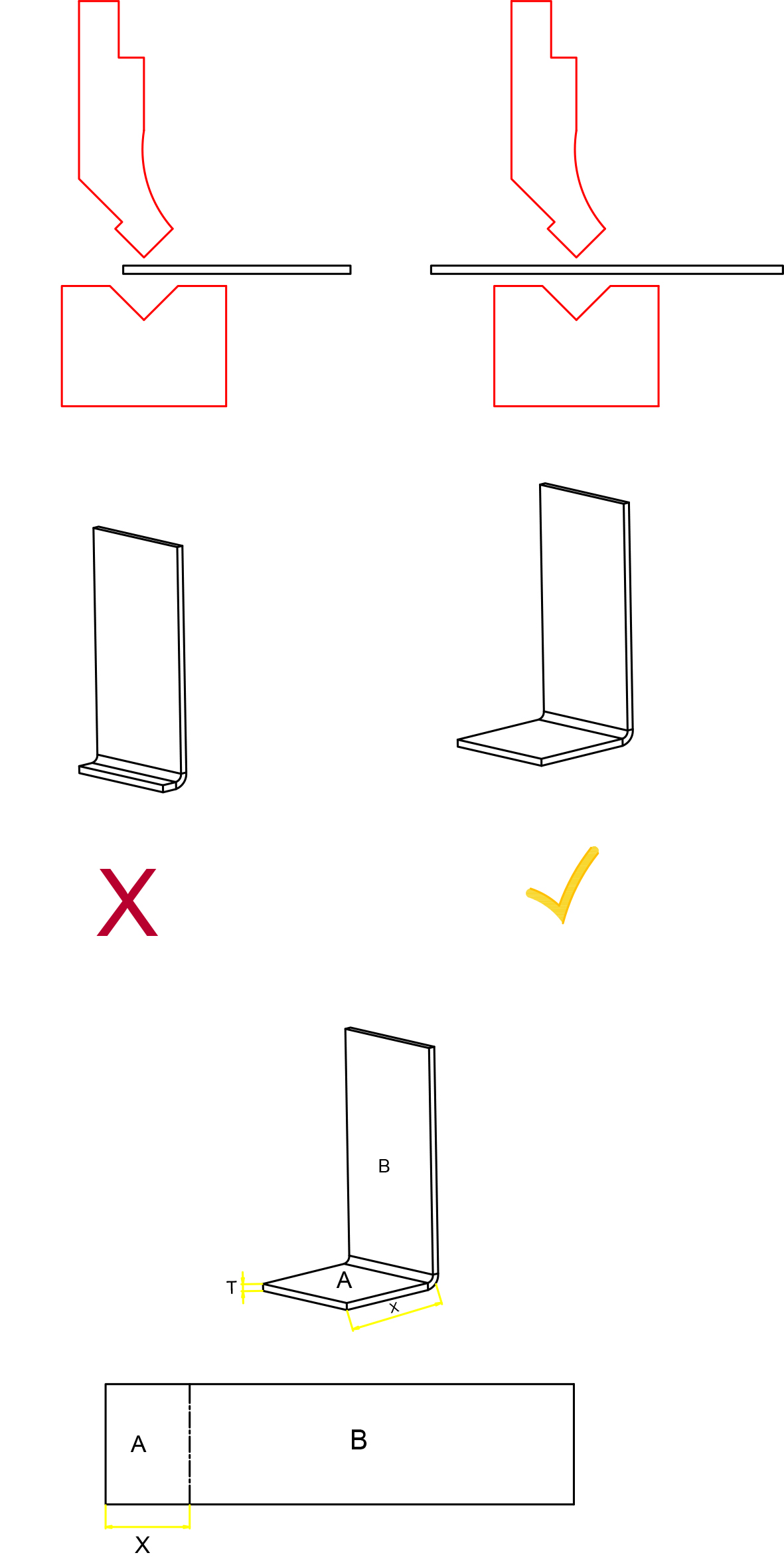

MINIMUM LENGTHS OF BENDING EDGES

The part on the left cannot be bent because one of its edges is too short compared to the bending mold.

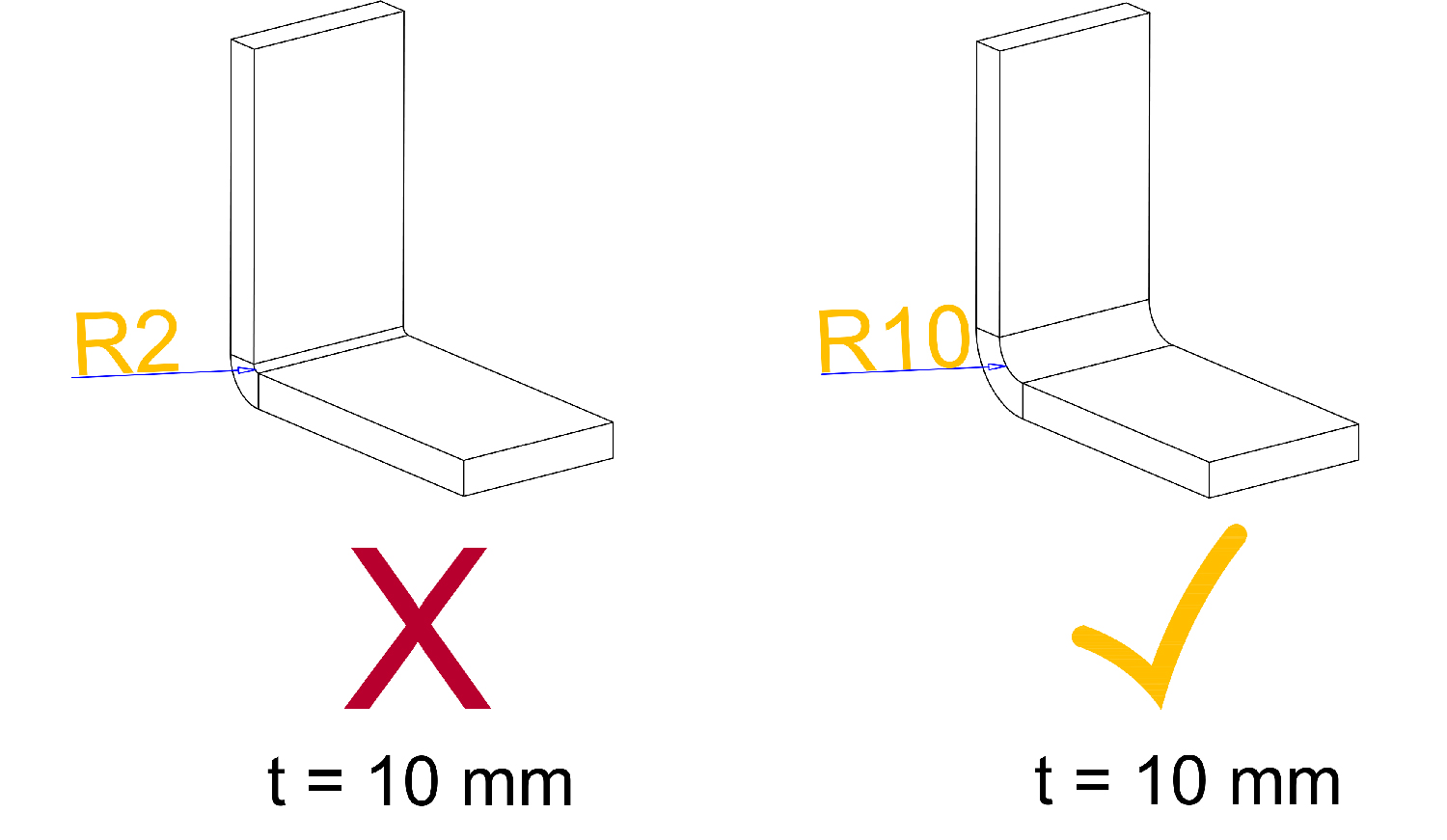

RADIUS (INTERNAL RADIUS OF BENDING)

The radius of the part on the right is determined appropriately according to the sheet thickness. It is bendable. The radius of the part on the left is too small according to the sheet thickness, so it cannot be bent.

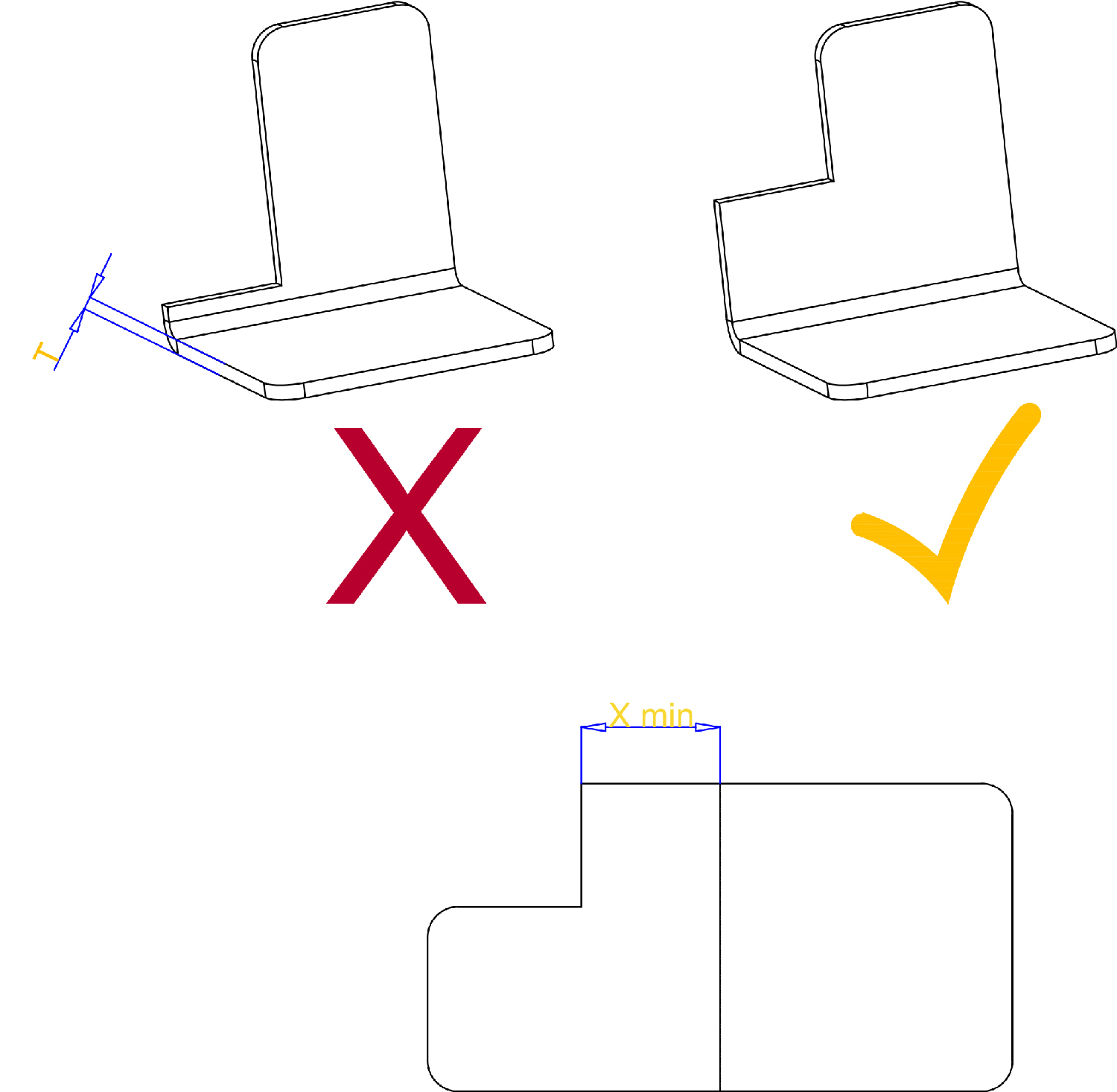

DESIGN OF RELIEFS IN BENDING

The distance of the reliefs to the bending point should be appropriate. Otherwise, while the edges are bent correctly, the reliefs will be deformed.

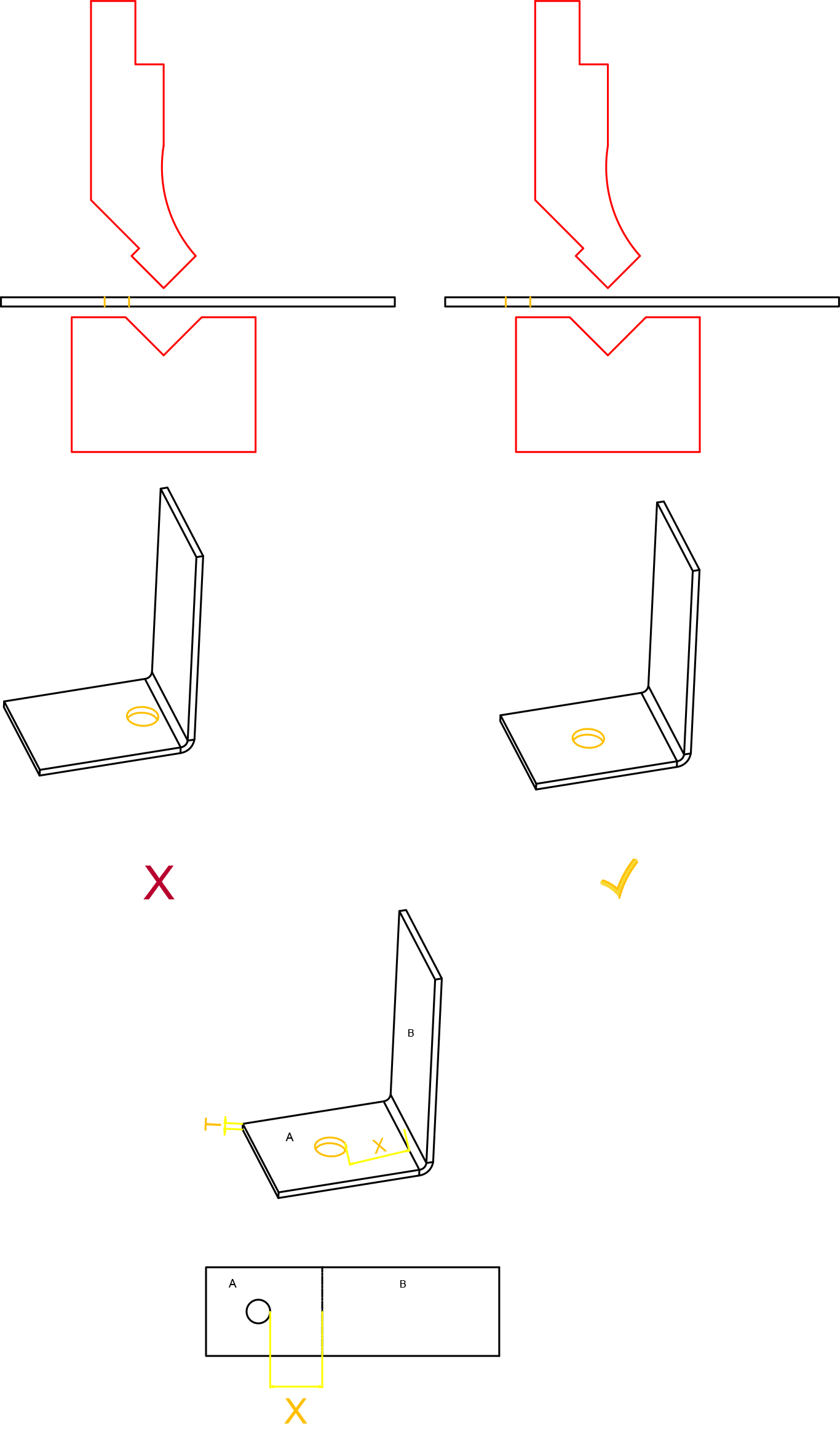

HOLE DESIGN

If holes are placed closer to the bending point than reference values, they will deform during bending.

RELIEF BENDING

In relief bends, placing reliefs between the bending area and adjacent edges, with a width of at least the sheet thickness, will reduce the risk of tearing the sheet.